Imagine steering a company that’s been a cornerstone of the industry for over a century. You’ve seen trends come and go, weathered economic storms, and consistently delivered quality. That’s the impressive legacy of one of our recent clients—a rubber company with 115 years of history and over 200 employees. But even with such a rich heritage, they knew that to thrive in today’s world, evolution was key. And evolution, for them, meant embracing technology and streamlining operations like never before.

The Challenge: Upgrading Tech, But Not Before Upgrading Strategy

This wasn’t just about installing a new ERP system. Our client understood that technology alone wouldn’t solve everything. They were dealing with growth, new product lines, and the complexities of managing a large team. Before investing in a major ERP upgrade, they wanted to optimize their existing processes and truly understand their needs. They needed to ensure the new technology would support, not complicate, their operations.

Our Strategy: Laying the Foundation with Lean

We partnered with them to develop a multi-faceted strategy focused on lasting improvement:

- Lean Training for Everyone: We didn’t just teach Lean principles to the management team. We brought the entire organization—production, sales, administration, and quality—into the conversation. Everyone gained a shared understanding of Lean Thinking, fostering a culture of continuous improvement.

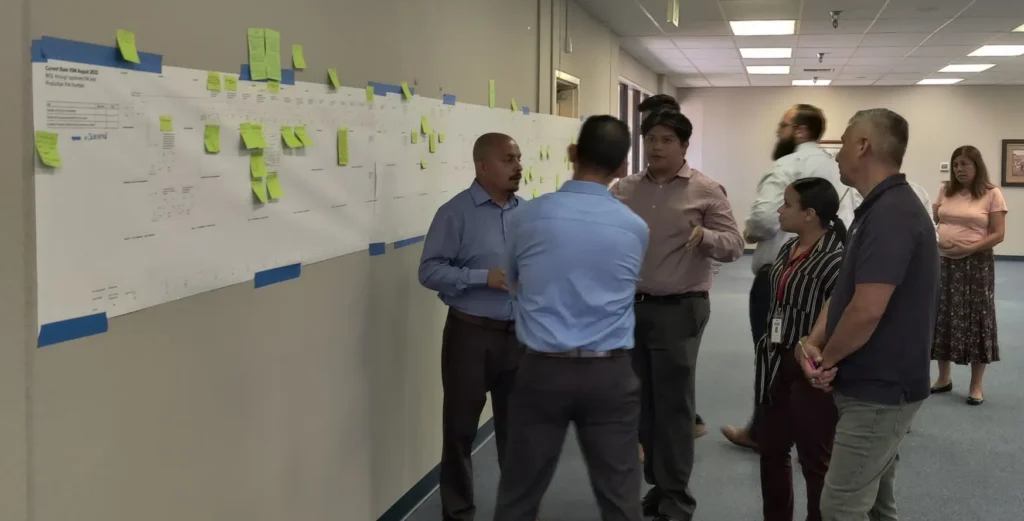

- Value Stream Mapping: Unveiling the Hidden Pathways: We meticulously mapped all office and production processes. This wasn’t just a surface-level exercise. It was a deep dive into how things actually worked. This allowed them to identify bottlenecks, inefficiencies, and opportunities for improvement.

- Creating a Rock-Solid Requirements Document: Armed with the insights from the Value Stream Mapping, we helped them develop a comprehensive Requirements Document for their ERP selection. This ensured they chose a system that truly aligned with their specific needs and Lean goals.

The Outcome: Seamless Integration and Future-Proofing

The impact was profound:

- Successful ERP Implementation: The ERP selection process was completed, and they were ready to move forward with confidence.

- Leveraging the System for Lean: The Value Stream Maps became a crucial tool for both the company and their ERP vendor. They provided a clear roadmap for leveraging the new system to support Lean Manufacturing principles. This meant faster adoption and maximized value from their investment.

How Lean Made All the Difference:

- Empowered Employees: Lean training wasn’t just about learning theory; it was about experiencing how these principles could be applied in their daily work. They practiced concepts like “Pull” to achieve “Flow” and learned to identify and eliminate all forms of waste.

- Visualizing the Operation: Value Stream Mapping revealed the big picture, empowering the team to see the interdependencies of processes and pinpoint areas for impactful improvements.

- Targeted Requirements: The Requirements Document ensured the new ERP system would handle the unique complexities of their business, including detailed scenarios for inventory and quality tracking.

The Ripple Effect:

By investing in Lean training and process improvement, this historic company didn’t just upgrade their technology. They upgraded their entire operation. They gained capacity, improved customer service and delivery, and strengthened their financial position. More importantly, they empowered their team to continuously identify and overcome obstacles, ensuring they remain competitive for another 115 years and beyond.

Is Your Company Ready for Transformation?

Whether you’re facing a tech upgrade, rapid growth, or simply looking to optimize your processes, Lean methodologies can provide the foundation for lasting success. Contact Engage Forward today to learn how we can help you unlock your company’s potential.