How Leaders Transformed a Rocky Startup into a High-Performance Operation

Imagine launching a critical project for a $1.5 billion architectural masterpiece, only to find yourself in the middle of operational chaos. That’s exactly what happened at the start of a high-stakes manufacturing launch for a landmark museum.

Picture this: a factory was launched to manufacture patented, fire-resistant composite panels for a $1.5B architectural museum – a complex job with tight tolerances, seismic engineering, and a 100-year warranty. Yet there were understaffed teams, zero quality controls, and a workplace struggling with safety, all while battling the curveballs of the COVID-19 pandemic. The launch faced mission-critical timelines under global scrutiny—and failure wasn’t an option.

But here’s the good part: failure wasn’t an option. It couldn’t be. And that’s where we began transforming a potential disaster into a resounding success story.

The Initial Mess:

Let’s be real. The factory was facing some serious hurdles. It was a rough start:

- Staffing and Training Nightmare: Severely understaffed and facing a huge learning curve.

- Operational Void: No production standards, no logical flow, and a complete lack of visual layout.

- Quality Control? What’s That?: Zero quality controls and a haphazard delivery system.

- Safety First? Not Quite: An unsafe, disorganized workplace with poor air quality.

- Lean? Not So Much: No Lean systems, planning, or leadership alignment to speak of.

Our Strategy: Turning the Tide

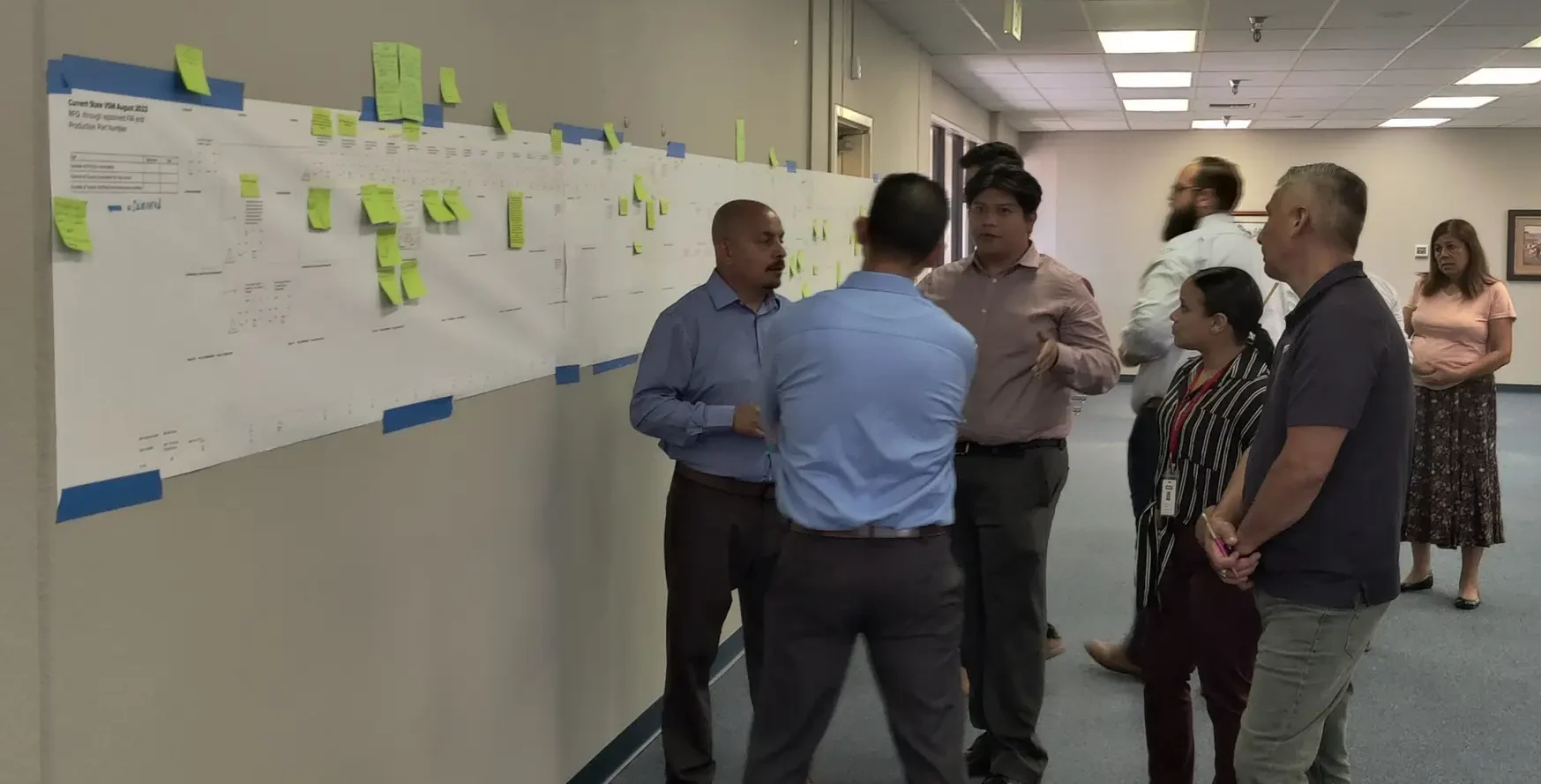

We rolled up our sleeves and went to work on a full-scale Lean transformation over 18 months. Our approach was comprehensive:

- People Power: Hired 100+ new employees and created robust training programs. We didn’t just train; we built a learning organization, delivering 731 hours of training in Lean, TWI, leadership, problem-solving, and more!

- Process Perfection: We ran Kaizen events that slashed a staggering 7,100 miles of unnecessary walking! We redesigned the factory for optimal flow, implemented visual management, and introduced 5S Visual Workplace systems.

- Logistics Like Clockwork: We built a bulletproof pack-out plan, delivery system (35 trailers!), and a pull-based inventory system perfectly synced with the installation schedule.

The Results: Numbers Don’t Lie

The proof is in the pudding. Here’s a snapshot of the incredible transformation:

- Staffing Skyrocketed: From <20 to 120+ employees, doubling production to meet demand.

- Walking? Avoided!: 7,100 miles of wasted walking eliminated—that’s like walking from San Francisco to New York to Miami!

- Time Regained: Saved 2,368 hours (99 days!) of work time, redirecting effort to value-added activities.

- Training Triumph: 731 hours of training delivered, embedding critical thinking at every level.

- Space Liberated: 2,117 sq ft of floor space freed up, improving flow and safety.

- Deadlines Dashed: Finished a full month ahead of schedule!

- Safety Sorted: Transformed from non-compliant to fully OSHA & SDS compliant.

- Logistics Launched: Built and deployed a complete logistics system with 35 trailers.

- Lean Achieved: Created a daily visual management and continuous improvement culture.

How We Did It: The Lean Toolkit

Our secret weapons? Lean tools!

- Kaizen Events: Eliminated motion waste and boosted efficiency.

- Visual Workplace (5S): Crafted a safe, organized, and visually managed environment.

- TWI & Leadership Training: Developed a skilled, confident workforce ready for anything.

- 4DX: Provided the structure to execute strategy and keep goals in sight.

- Pull Systems & Flow: Ensured production aligned with installation sequencing and just-in-time logistics.

The Takeaway:

This case study showcases the power of Lean transformation when leadership is committed. We turned a chaotic situation into a world-class Lean operation, delivering not just a project, but a piece of architectural history, on time, with unparalleled efficiency and employee engagement.

Testimonials:

“This project shows what Lean can do when leadership commits. We created a fully aligned, high-performing team — and a Lean factory capable of delivering architectural history.” — V.P. of Lean Operations

Are you facing similar challenges? Let’s talk about how we can bring the same results to your organization. Contact us today to start your Lean transformation journey!